Add description, images, menus and links to your mega menu

A column with no settings can be used as a spacer

Link to your collections, sales and even external links

Add up to five columns

Add description, images, menus and links to your mega menu

A column with no settings can be used as a spacer

Link to your collections, sales and even external links

Add up to five columns

Polyalphaolefin (PAO), Esters & Alkylated Naphthalene (AN)

April 20, 2022 3 min read

Polyalphaolefin (PAO) base oil can’t do it alone! Enter Esters and Alkylated Naphthalene (AN).

Torco’s high tech base oils for high tech vehicles

100% PAO engine oils must be mixed with other base oils to maximize additive performance. Once upon a time this was accomplished with esters, but Alkylated Naphthalene has recently reared its head as a superior alterative, giving motor oils more stability at high temperatures.

Did you know that full synthetic PAO motor oils are never 100% PAO? The problem is solubility. The same way that salt dissolves in water but not in oil, PAO synthetic base oils aren’t able to dissolve enough additives. That’s a problem for high performance engine oils that need additional antioxidant, antiwear, rust protection and detergent additives.

The result? All full synthetic PAO oils include another synthetic “co-base stock”. For many years, the default choice was an ester – these are widely available high performing lubricants that are typically used in compressor and turbine oils. But today we have new and better technologies available – enter Alkylated Naphthalene.

Don’t get esters wet

How do you make an ester? You react an acid and an alcohol, and it produces an ester, plus some water (which must then be removed). This reaction leads to the Achilles heel of all esters. If you add water to an ester, you drive the rection the other way and produce acids and alcohols. Acids are terrible for engines – they can corrode big and small end bearings, and vastly reduce the life of the oil.

Unfortunately, water is everywhere. It’s in the air and it is created when you burn fuel. There’s really no avoiding it.

Not all esters are created equal

This is a diester. Water attacks the oxygens, and in a diester the oxygens are very exposed. There’s really nothing stopping water from pulling these molecules apart. Once common in engine oils, use of these base oils has become restricted to applications like dry gas compression, where we can ensure low levels of interaction with water.

This is a polyol ester. The oxygens are less exposed and pointed into the center of the molecule; this makes it more difficult for water to physically interact with and pull apart the base oil. Polyol esters are the preferred choice for high temperature applications like aviation turbine oils, and represent a big upgrade over their diester cousins. Higher performance engine oils moved to this technology a few decades ago as a more stable co-base stock.

Enter Alkylated Naphthalene

For even better performance, consider the alkylated naphthalenes (ANs). This class of base oil has no real weakness when it comes to interaction with water, as you can’t reverse the production reaction.

Moreover, there is a growing body of evidence that suggests ANs blended with PAOs and Group II/III base oils offer superior stability when compared with similar ester blends. This is critical in high performance engines which run hotter and at higher loads – a recipe for engine deposit formation.

When you are too strong for your own good

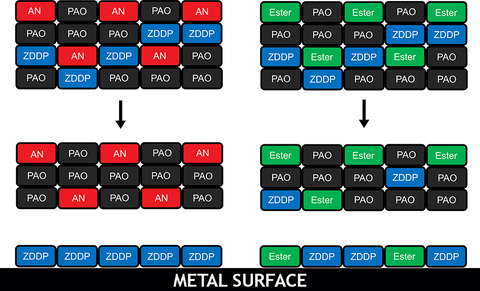

A secondary issue facing ester base oils is that they sometimes compete with surface acting chemicals in the additive package. What are these? Antiwear, rust preventatives, corrosion inhibitors and detergents all need to “stick” to engine surfaces to be effective. The problem? Esters are also “sticky” and their affinity for metals can mean the ester pushes those essential additives out of the way.

Aklylated Naphthalenes don’t exhibit this same behavior. This is means that additive quantities can be reduced in the engine oil while maintaining the same level of protection. This in turn reduces engine deposits because spent additives mostly turn to sludge and varnish.

The next step in motor oil evolution

Torco understands motor oils need to change with the times. As new molecules are engineered and state of the art research comes to light, Torco integrates them into our product line. Alkylated Naphthalenes are just one of the many new technologies that Torco is bringing to you and your engine to ensure that you stay ahead of the pack.

Subscribe

Sign up to get the latest on sales, new releases and more …